R PANEL

R-PANEL VS AG PANEL

R-panel and Ag Panel are both very popular metal wall and roof panels; however, because of their similarity there is often confusion as to which panel may be best for a particular application. Both panels are manufactured by tens, if not hundreds, of companies and it is important to know that not all panels are created equal because there are different levels of quality and performance. Just as facial tissues run the gamut from tissues with aloe for extra comfort all the way to lower-quality tissues that feel like sandpaper on your nose, R-Panels and Ag Panels have differing levels of performance when it comes to the steel substrate and paint system that is utilized. Therefore, end-users need to take care and ask questions about the panels to ensure quality and performance are in sync with long-term end-user expectations.

WHAT ARE R-PANEL AND AG PANEL?

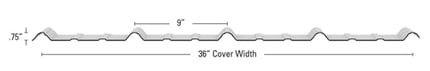

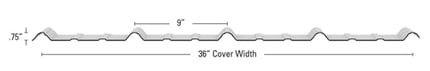

Ag Panel is a slang term for one of the most popular exposed fastener metal roofing and siding profiles in the construction industry. Post-frame (aka pole barn) buildings and residential metal roofing represent the two largest construction segments for Ag Panel usage. While there may be some minor differences in specifications and details, the drawings below represent the most popular Ag Panel profile in use today. The distinguishing feature of this popular Ag Panel are ¾” tall major ribs that are spaced 9” on-center.

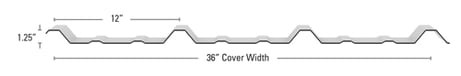

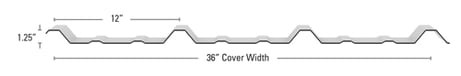

WHAT IS AN R-PANEL?

R-Panel is a multi-use exposed fastener metal wall and roof panel that was originally designed for use in pre-engineered metal buildings. However, since its inception, the use of R-Panel has expanded into many other areas, such as residential metal roofing. The drawings below showcase the distinguishing characteristics of an R-Panel. Note that major ribs are 1.25” tall and spaced 12” on center.

HOW R-PANEL IS USED

Both R-Panel and Ag Panel are great multi-purpose panels that are utilized in a wide variety of applications, including walls and roofs on commercial and residential projects. When it comes to engineered buildings, these panels are the industry standard in two different segments. R-Panel is the industry-standard panel for the Pre-Engineered Metal Building Industry while Ag Panel is the industry standard panel for the Post Frame industry. The reason for the difference goes back many decades which we will address in the next sections.

R-PANEL AND AG PANEL STRENGTH

The standard gauge for R-Panel is 26 gauge while the standard gauge for Ag Panel is 29 gauge. Gauge is referred to in a numerical scale, with larger numbers equating to thinner steel; therefore, 26 gauge is thicker than 29 gauge. Both R-Panel and Ag Panel are also available in heavier gauges to meet specific engineering requirements on projects. To better understand R-Panel and AG Panel differences, let’s take a look at how metal buildings and post frame buildings are different. Metal buildings are supported with steel structural and substructural members while post frame buildings are supported with wood structural and sub-structural members.

R-PANEL AND AG PANEL STRENGTH

POST FRAME BUILDING

To reduce the amount of framing material required, it is desirable to spread the framing as far apart as possible. R-panel’s thicker 26 gauge steel in combination with the beefy/robust major ribs enhance the strength and load-bearing characteristics of the panel and therefore can span greater spacing between framing members. In some climates, sub-structural spacing on pre engineered metal buildings can be as much as 5 ‘on center. Roof framing on post frame buildings is typically spaced 2’ on center. This narrower gap on a post frame building means a lighter gauge panel with less robust major ribs is sufficient for the required engineering. Hence, an Ag Panel is the standard for post frame buildings. If panels are being installed over open framing with greater on-center spans, R-Panel is most likely a better option. If panels are being installed over a solid deck, such as residential metal roofing applications, the difference in strength has less of an impact. While a 26 gauge R-Panel is still stronger than a 29 gauge Ag Panel, fastening attachment patterns can help make up the difference in strength to ensure engineering requirements are met. Especially in the southwest, R-Panel is also used extensively for residential applications. End uses include residential metal roofing and buildings that combine both work and living spaces. These applications are becoming more popular and are commonly referred to as a barndominium or shouse. Although your contractor has flexibility, the most common practice is to use an R-Panel if the structure is a pre-engineered metal building and use an Ag-Panel if the structure is a post frame building.

R-PANEL AND AG PANEL AESTHETICS

Well, like many things in life, beauty is in the eye of the beholder. That analogy also applies to R-Panel and Ag Panel. As shown earlier, here are the major differences.

R-PANEL

AG PANEL

• R-Panel major rib height is 1.25” while Ag Panel major rib height is .75”

• R-Panel has major ribs 12” on center while Ag panel has major ribs 9” on center

Take a look at the drawings above and imagine them side by side on a building. Aesthetically, the visual appearance of the panel profile is the difference between the two panel types, which is why the final decision often comes down to personal preference. Some people prefer the bold appearance of an R-Panel while others prefer the more subtle appearance of an Ag Panel.

Trim, or flashings, on a building is another aesthetic difference that can be a consideration. Flashings are the components that tie-in or connect the metal panels together and are installed at the intersections and terminations of metal panels to seal the roof and prevent water from entering the building envelope. Many homeowners prefer smaller flashings so there is more visual emphasis on the roof itself rather than the flashings. In other words, it is preferable for flashings to blend-in rather than stand-out. In this case, an Ag Panel is preferable because the ¾” rib height uses smaller flashings than an R-panel with the 1.25” rib height.

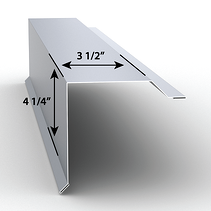

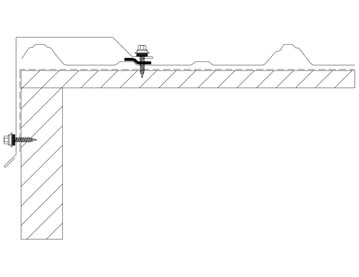

The rake on a building runs from the eave to ridge along the roofline. Shown below is a drawing and installation detail of a rake, or gable, flashing for an Ag-Panel. Because the rake flashing covers the metal panel on the roof, the flashing is designed accordingly. Therefore, since an R-Panel rib is taller and wider than an Ag-Panel rib, the flashing is also larger.